Xaiv cov txheej txheem tsim khoom zoo rau cov khoom siv hlau yog qhov tseem ceeb. Koj yuav tsum xav txog yam xws li precision, ntim, thiab tus nqi. CNC machining muaj qhov tsis sib haum xeeb thiab yooj yim, ua rau nws zoo tagnrho rau kev khiav me me ntawm qhov nyuaj. Ntawm qhov tod tes, hlau casting excels nyob rau hauv high-volume ntau lawm vim nws cov nqi-zoo thiab ceev. Txhua txoj kev nws muaj nws qhov zoo thiab qhov txwv. Koj cov kev xav tau tshwj xeeb yuav txiav txim siab seb cov txheej txheem twg haum rau koj zoo tshaj plaws. Kev nkag siab txog qhov sib txawv no pab koj txiav txim siab paub, ua kom koj cov khoom ua tau raws li qhov xav tau tshwj xeeb thiab zoo.

CNC Machining rau Custom Metal Parts

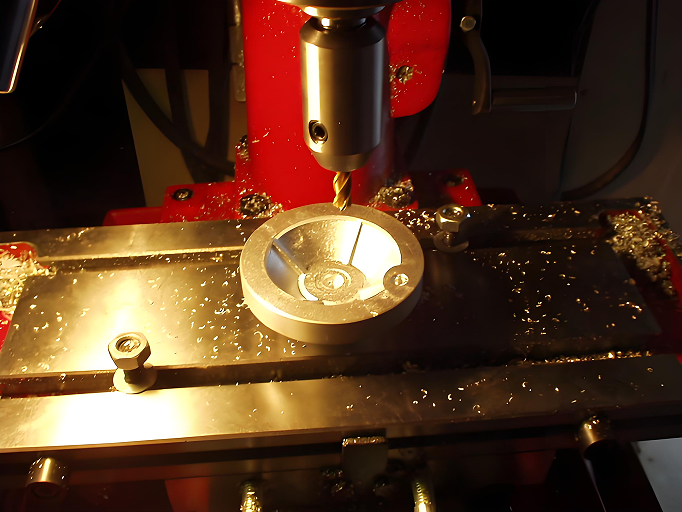

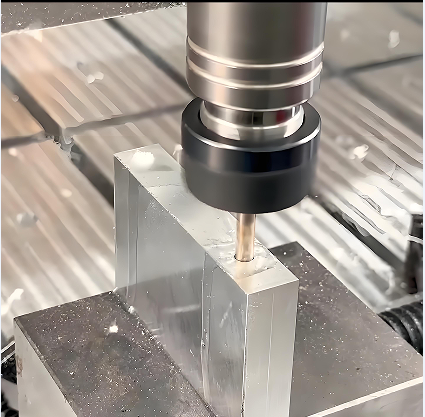

CNC Machining kev ua haujlwm

CNC machining stands raws li ib tug ntau yam kev tsim txheej txheem uas tso cai rau koj los tsim kev cai hlau qhov chaw nrog zoo kawg li precision. Cov txheej txheem no suav nrog kev siv lub tshuab computer tswj los tsim cov hlau rau hauv cov ntawv xav tau. Koj tuaj yeem ua tiav cov qauv tsim thiab cov duab geometry nyuaj uas yuav nyuaj nrog lwm txoj hauv kev. CNC tshuab ua haujlwm los ntawm kev ua raws li cov lus qhia programmed, ua kom txhua qhov ua tau raws li cov lus qhia meej. Qhov kev txiav txim siab no ua rau CNC machining zoo tagnrho rau kev tsim cov khoom muaj tseeb nrog nruj kam rau ua, tshwj xeeb tshaj yog thaum cuam tshuam nrog cov khoom me me lossis cov niche.

Cov txiaj ntsig ntawm CNC Machining

Thaum koj xaiv CNC machining rau koj cov kev cai hlau qhov chaw, koj tau txais ntau yam zoo:

- Siab Precision: CNC machining excels hauv kev xa khoom nrog qhov tseeb tshwj xeeb. Qhov no yog qhov tseem ceeb thaum koj xav tau cov khoom uas haum txig rau hauv cov rooj sib txoos loj.

- Cov qauv tsim: Lub peev xwm los tsim intricate thiab complex designs teem CNC machining sib nrug. Koj tuaj yeem tsim cov khoom nrog cov ncauj lus kom ntxaws uas lwm cov txheej txheem yuav nyuaj rau rov ua dua.

- Durability: Cov khoom tsim los ntawm CNC machining yog paub txog lawv cov robustness. Qhov no durability xyuas kom meej tias koj cov khoom tiv thaiv kev thov.

- Material Versatility: CNC machining ua haujlwm nrog ntau yam khoom siv, tso cai rau koj xaiv qhov kev xaiv zoo tshaj plaws rau koj cov kev xav tau tshwj xeeb.

- Kev ua tau zoo: Rau nruab nrab mus rau kev ua haujlwm siab, CNC machining muaj kev ua haujlwm zoo, ua rau nws muaj txiaj ntsig zoo xaiv rau qhov tseeb.

Kev txwv ntawm CNC Machining

Txawm tias nws cov txiaj ntsig ntau, CNC machining muaj qee qhov kev txwv:

- Nqi rau Tsawg Volume: Rau kev tsim khoom me me, tus nqi pib pib tuaj yeem siab. Qhov no yuav tsis yog qhov kev xaiv pheej yig tshaj yog tias koj tsuas yog xav tau ob peb ntu.

- Khoom pov tseg: CNC machining koom nrog kev txiav cov khoom, uas tuaj yeem ua rau khib nyiab. Qhov no yuav tsis zoo tagnrho yog tias koj ua haujlwm nrog cov khoom kim.

- Complexity hauv Teeb: Kev teeb tsa lub tshuab CNC xav tau cov neeg ua haujlwm txawj thiab kev ua haujlwm zoo. Qhov kev nyuaj no tuaj yeem ua rau lub sijhawm ua haujlwm rau cov haujlwm tshiab.

Los ntawm kev nkag siab txog cov yam ntxwv ntawm CNC machining, koj tuaj yeem txiav txim siab zoo dua yog tias nws yog txoj hauv kev rau koj cov khoom siv hlau. Txawm hais tias koj tseem ceeb tshaj qhov tseeb, qhov nyuaj, lossis kev ua haujlwm ntev, CNC machining muaj kev txhim khu kev qha rau ntau qhov kev xav tau.

Hlau Casting rau Custom Metal Parts

Hlau Casting txheej txheem

Hlau casting yog txheej txheem tsim khoom tsim uas koom nrog tsim pwm los tsim koj cov khoom siv hlau. Koj ncuav hlau molten rau hauv cov pwm no, cia nws txias thiab solidify tag nrho. Txoj kev no tuaj yeem tsim qhov sib txawv thiab nyuaj ntawm ntau qhov ntau thiab tsawg. Cov txheej txheem sib txawv, xws li tuag casting, yog tsim los ua kom tau raws li cov qauv tsim thiab kev tsim khoom. Kev tuag casting, piv txwv li, siv lub zog siab los txhaj cov hlau molten rau hauv cov pwm hlau, uas tuaj yeem rov siv tau ntau zaus. Cov txheej txheem no yog tshwj xeeb tshaj yog zoo rau tsim geometrically complex qhov chaw.

Cov txiaj ntsig ntawm Hlau Casting

Thaum koj xaiv rau hlau casting, koj tau txais ntau yam zoo:

- Tsim Flexibility: Hlau casting tso cai rau koj los tsim cov duab sib txawv thiab cov geometry nyuaj uas yuav nyuaj nrog lwm txoj hauv kev.

- Nqi-zoo: Rau cov khoom ntim siab, cov hlau casting ua pov thawj tias tus nqi zoo vim nws muaj peev xwm rov siv cov pwm thiab tsim cov khoom sai.

- Material Versatility: Koj tuaj yeem siv ntau yam hlau hauv casting, muab qhov yooj yim rau koj xaiv cov khoom siv zoo tshaj plaws rau koj daim ntawv thov.

- Kev Ua Tau Zoo: Hlau casting excels nyob rau hauv ua kom muaj nuj nqis loj ntawm qhov chaw zoo, ua rau nws zoo tagnrho rau kev lag luam uas xav tau ntau lawm.

Kev txwv ntawm Hlau Casting

Txawm tias nws cov txiaj ntsig, hlau casting muaj qee qhov kev txwv:

- Tus nqi pib pib: Tsim cov pwm tuaj yeem kim, tshwj xeeb tshaj yog rau cov qauv tsim. Qhov no yuav tsis yog kev lag luam rau cov khoom ntim qis.

- Nto tiav: Cov khoom tsim los ntawm kev casting yuav xav tau cov txheej txheem tiav ntxiv kom ua tiav qhov zoo ntawm qhov chaw.

- Dimensional raug: Thaum casting tuaj yeem tsim cov duab nyuaj, ua tiav qhov kev ua siab ntev tuaj yeem nyuaj piv rau CNC machining.

Los ntawm kev nkag siab txog cov yam ntxwv ntawm cov hlau casting, koj tuaj yeem ntsuas tau zoo dua yog tias nws yog cov txheej txheem zoo rau koj cov khoom siv hlau. Txawm hais tias koj ua qhov tseem ceeb ntawm kev tsim qauv yooj yim, kev ua tau zoo, lossis kev tsim khoom, hlau casting muaj kev daws teeb meem rau ntau qhov kev xav tau.

Kev sib piv ncaj qha ntawm CNC Machining thiab Hlau Casting

Complexity thiab tsim Flexibility

Thaum nws los tsim kev cai hlau qhov chaw, ob qho tib si CNC machining thiab hlau casting muaj qhov tshwj xeeb zoo nyob rau hauv cov nqe lus ntawm complexity thiab tsim yooj.CNC machiningexcels nyob rau hauv ua qhov chaw nrog intricate cov ntsiab lus thiab nruj tolerances. Koj tuaj yeem ua tiav cov qauv tsim thiab rov ua dua, ua rau nws zoo tagnrho rau cov khoom siv uas yuav tsum tau muaj qhov tshwj xeeb. Cov txheej txheem no tso cai rau kev hloov kho yooj yim, ua rau koj sim thiab kho cov qauv tshiab yam tsis tas yuav tsim pwm tshiab.

Ntawm qhov tod tes,hlau castingci nyob rau hauv nws lub peev xwm los tsim complex duab nrog nyias phab ntsa thiab intricate cov ntsiab lus. Nws tso cai rau kev tsim cov hollow qhov chaw thiab cov kab noj hniav sab hauv uas tej zaum yuav nyuaj rau kev ua tiav los ntawm machining. Thaum casting tej zaum yuav tsis phim qhov precision ntawm CNC machining, nws muaj qhov tsim tau yooj yim, tshwj xeeb tshaj yog rau cov khoom loj.

Tus nqi thiab ntim ntau lawm

Cov nqi txiav txim siab ua lub luag haujlwm tseem ceeb hauv kev xaiv ntawm CNC machining thiab hlau casting rau koj cov khoom siv hlau.CNC machiningzoo li yuav kim dua rau cov khoom ntim qis vim yog cov nqi pib thiab cov khoom siv pov tseg. Txawm li cas los xij, nws dhau los ua tus nqi zoo rau nruab nrab mus rau kev tsim khoom siab, qhov twg precision thiab complexity yog qhov tseem ceeb.

Piv txwv li,hlau castingua pov thawj tias yuav txuag tau ntau dua rau cov khoom ntim siab. Lub peev xwm los rov siv cov pwm txo cov nqi ntau, ua rau nws yog qhov kev xaiv zoo tshaj plaws rau ntau lawm. Thaum cov pwm tsim thawj zaug tuaj yeem raug nqi, tus nqi ib-unit poob qis vim qhov ntim ntau lawm. Qhov no ua rau casting qhov kev xaiv siv tau rau kev lag luam uas xav tau ntau qhov chaw sai sai.

Khoom Compatibility

Material compatibility yog lwm qhov tseem ceeb thaum txiav txim siab ntawm CNC machining thiab hlau casting.CNC machiningmuaj ntau yam khoom siv xaiv, tso cai rau koj xaiv cov khoom siv zoo tshaj plaws rau koj cov kev xav tau tshwj xeeb. Txawm hais tias koj xav tau hlau xws li txhuas, hlau, lossis titanium, CNC machining tuaj yeem ua raws li koj qhov yuav tsum tau ua.

Hlau casting, thaum muaj ntau yam, muaj ntau yam khoom siv tsawg dua piv rau CNC machining. Nws ua haujlwm zoo nrog cov hlau xws li txhuas, zinc, thiab magnesium, tab sis tej zaum yuav tsis haum rau txhua yam ntaub ntawv. Txawm hais tias qhov kev txwv no, casting tseem yog qhov kev xaiv txhim khu kev qha rau kev tsim cov khoom ruaj khov thiab ruaj khov.

Los ntawm kev nkag siab txog qhov sib txawv no, koj tuaj yeem txiav txim siab paub txog cov txheej txheem twg zoo tshaj plaws rau koj cov khoom siv hlau. Txawm hais tias koj ua qhov tseem ceeb tshaj plaws, kev ua tau zoo, lossis cov khoom siv sib raug zoo, ob qho tib si CNC machining thiab hlau casting muaj txiaj ntsig zoo rau ntau yam kev tsim khoom xav tau.

Xaiv Cov Txheej Txheem Zoo rau Cov Ntawv Thov tshwj xeeb

Kev xaiv ntawm CNC machining thiab hlau casting rau koj cov khoom siv hlau yuav tsum tau ua tib zoo xav txog ntau yam. Txhua txoj hauv kev muaj cov txiaj ntsig tshwj xeeb thiab cov kev txwv, ua rau nws tseem ceeb los ua kom koj xaiv nrog koj cov kev xav tau tshwj xeeb.

Yam uas yuav tau xav txog

-

Ntau lawm ntim: Yog tias koj xav tau ntau qhov chaw, hlau casting feem ntau ua pov thawj zoo dua. Lub peev xwm los rov siv cov pwm txo cov nqi ntau hauv cov ntim ntau lawm. Txawm li cas los xij, rau cov khoom me me, CNC machining tej zaum yuav pheej yig dua txawm tias nws cov nqi pib ntau dua.

-

Precision thiab kam rau ua: CNC machining excels nyob rau hauv xa cov khoom nrog nruj tolerances thiab siab precision. Qhov no ua rau nws zoo tagnrho rau cov ntawv thov uas cov lus qhia meej yog qhov tseem ceeb. Hlau casting, thaum muaj peev xwm tsim cov duab nyuaj, yuav tsis ua tiav tib theem ntawm precision li CNC machining.

-

Cov ntaub ntawv xav tau: Xav txog cov ntaub ntawv uas koj npaj yuav siv. CNC machining muaj ntau yam khoom xaiv, haum rau cov hlau xws li txhuas, hlau, thiab titanium. Hlau casting ua haujlwm zoo nrog cov hlau xws li txhuas, zinc, thiab magnesium tab sis yuav tsis haum txhua yam khoom.

-

Tsim Complexity: Rau intricate designs nrog cov ncauj lus kom ntxaws nta, CNC machining muab unmatched yooj. Koj tuaj yeem hloov kho cov qauv yooj yim yam tsis tsim cov pwm tshiab. Hlau casting, txawm li cas los xij, tso cai rau kev tsim cov duab nyuaj nrog cov kab noj hniav sab hauv, uas yuav nyuaj rau kev ua tiav los ntawm kev ua haujlwm.

-

Kev txiav txim siab nqi: Ntsuas qhov cuam tshuam ntawm tus nqi tag nrho. Thaum CNC machining tej zaum yuav muaj cov nqi nce siab dua, nws dhau los ua tus nqi tsim nyog rau nruab nrab mus rau kev ua haujlwm siab. Hlau casting muab cov nqi qis rau ib chav tsev hauv kev tsim khoom loj, ua rau nws tsim nyog rau kev lag luam uas xav tau ntau qhov chaw sai.

Cov Lus Qhia tshwj xeeb hauv kev lag luam

-

Automotive Kev Lag Luam: Rau cov khoom siv tsheb uas xav tau siab precision thiab lub zog, CNC machining feem ntau nyiam. Nws ua kom cov khoom ua tau raws li cov qauv nruj nruj thiab haum seamlessly rau hauv cov rooj sib txoos loj.

-

Aerospace Kev Lag Luam: Aerospace daim ntawv thov xav tau qhov chaw nrog qhov tseeb tshwj xeeb thiab ua haujlwm ntev. CNC machining muab qhov precision xav tau rau cov khoom tseem ceeb, ua kom muaj kev nyab xeeb thiab kev ua haujlwm.

-

Consumer Electronics: Hauv cov khoom siv hluav taws xob siv hluav taws xob, qhov tsim qauv tsis yooj yim thiab cov qauv teeb pom kev zoo yog qhov tseem ceeb, hlau casting tuaj yeem ua tau zoo. Nws tso cai rau kev tsim cov duab intricate zoo.

-

Khoom siv: Rau cov khoom lag luam uas xav tau qhov chaw muaj zog thiab ruaj khov, hlau casting muab cov nqi tsim nyog rau kev tsim khoom loj. Nws muab qhov tsim nyog lub zog thiab sib xws rau kev thov kev thov.

Los ntawm kev nkag siab txog cov xwm txheej no thiab cov lus pom zoo hauv kev lag luam, koj tuaj yeem txiav txim siab paub txog cov txheej txheem tsim khoom tsim nyog tshaj plaws rau koj cov khoom siv hlau. Txawm hais tias koj ua qhov tseem ceeb tshaj plaws, kev ua tau zoo, lossis cov khoom siv sib raug zoo, ua kom koj xaiv nrog koj daim ntawv thov kev xav tau ua kom tau txais txiaj ntsig zoo.

Kev xaiv ntawm CNC machining thiab hlau casting yuav tsum nkag siab txog lawv qhov sib txawv tseem ceeb. CNC machining muaj precision thiab yooj, ua rau nws zoo tagnrho rau intricate designs thiab me me zus tau tej cov khiav. Hlau casting, txawm li cas los xij, ua tau zoo hauv cov ntim ntau lawm nrog cov nqi-zoo thiab ceev. Txhawm rau xaiv cov txheej txheem kom raug, xav txog yam xws li ntim ntau lawm, kev xav tau precision, thiab cov khoom siv sib xws. Kev sab laj nrog cov kws tshaj lij tuaj yeem muab cov lus qhia tsim nyog, ua kom koj cov txheej txheem tsim khoom ua raws li koj qhov kev xav tau tshwj xeeb. Los ntawm kev ua kom koj cov kev xav tau ntau lawm nrog txoj kev tsim nyog, koj ua kom pom cov txiaj ntsig zoo rau koj cov khoom siv hlau.