Tsawg-ntim ntau lawm-txhaj tshuaj molding muab lub sijhawm hloov pauv kev ua si rau cov lag luam me. Koj tuaj yeem tsim cov khoom yas zoo nrog cov pwm tsawg thiab txo cov nqi teeb tsa. Txoj kev no txo cov nuj nqis ntxiv thiab txo cov kev pheej hmoo, ua rau nws zoo tagnrho rau kev pib ua haujlwm. Tsis zoo li cov khoom ntim siab, uas yuav tsum muaj kev nqis peev tseem ceeb, cov khoom ntim qis txo cov nqi no, tso cai rau koj txuag nyiaj. Nws kuj muab kev tsim qauv yooj yim, ua rau koj hloov pauv sai sai rau kev hloov pauv hauv kev lag luam. Los ntawm kev xaiv txoj hauv kev no, koj tau txais lub peev xwm los sim thiab kho cov khoom lag luam yam tsis muaj kev cuam tshuam nyiaj txiag ntawm kev tsim khoom loj.

Nkag siab Tsawg-Volume Production-Injection Molding

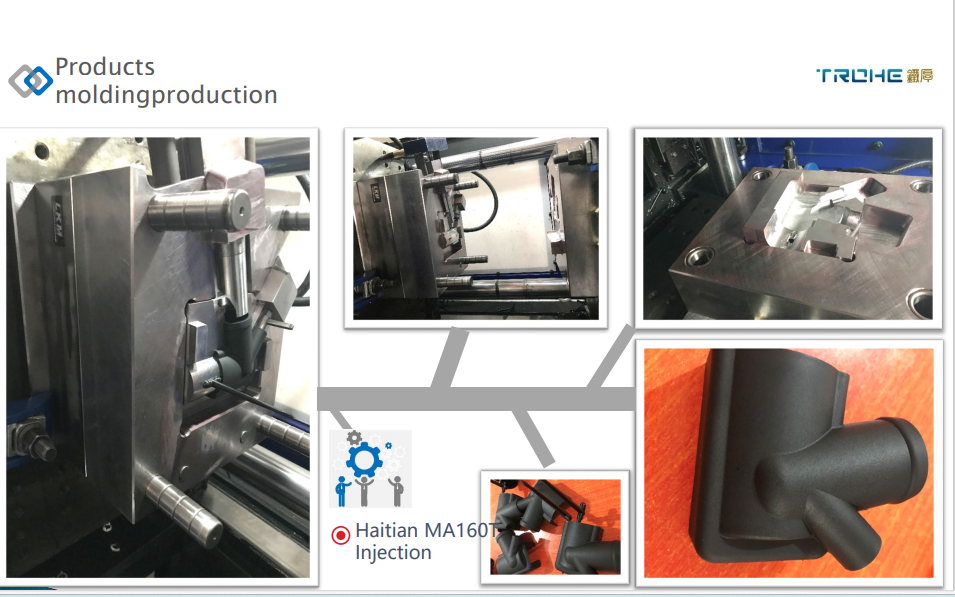

Txhais thiab Txheej txheem cej luam

Tsawg-ntim ntau lawm-txhaj tshuaj molding yog cov txheej txheem tsim khoom uas tso cai rau koj los tsim cov khoom me me ntawm cov khoom yas zoo. Txoj kev no ua haujlwm ua tus choj ntawm kev tsim qauv thiab kev tsim tawm tag nrho, ua rau nws zoo meej rau cov lag luam uas yuav tsum tau sim cov qauv tshiab lossis tsim cov khoom siv tsawg. Los ntawm kev siv cov pwm tsawg dua thiab txo cov nqi teeb tsa, koj tuaj yeem ua tiav cov txiaj ntsig tseem ceeb. Cov txheej txheem no tau siv dav hauv kev lag luam xws li cov khoom siv kho mob, cov khoom siv hluav taws xob, thiab tsheb rau kev tsim khoom luv luv thiab kev tsim qauv.

Cov txiaj ntsig rau Kev Lag Luam Me

Nqi-zoo

Ib qho ntawm qhov zoo tshaj plaws ntawm cov khoom ntim qis-txhaj tshuaj molding yog nws cov nqi-zoo. Cov txheej txheem molding cov txheej txheem feem ntau xav tau kev nqis peev loj hauv kev siv cuab yeej thiab teeb tsa. Txawm li cas los xij, nrog cov khoom ntim qis, koj tuaj yeem tsim cov khoom ntawm ib feem ntawm tus nqi. Qhov no ua rau nws yog qhov kev xaiv zoo tshaj plaws rau kev pib ua lag luam thiab cov lag luam me uas yuav tsum tau tswj hwm lawv cov peev nyiaj kom zoo. Koj tseem tuaj yeem txo cov khoom pov tseg thiab txo cov nqi cuab yeej, uas ua rau koj cov nyiaj txuag ntxiv.

Flexibility thiab ceev

Tsawg-ntim ntau lawm muab unmatched yooj thiab ceev. Koj tuaj yeem hloov kho sai sai rau kev hloov pauv hauv kev lag luam thiab cov neeg siv khoom xav tau yam tsis muaj kev cuam tshuam nyiaj txiag ntawm kev tsim khoom loj. Cov txheej txheem no tso cai rau koj los tsim cov kev hloov pauv tau yooj yim thiab nqa cov khoom lag luam sai dua. Txawm hais tias koj tab tom tsim cov qauv, sim cov qauv tshiab, lossis ua haujlwm rau cov lag luam niche, cov khoom ntim qis-txheej molding muab qhov agility koj xav tau kom nyob twj ywm sib tw.

Cov kauj ruam los pib nrog Tsawg-Volume Production

Kev pib ntawm cov khoom ntim qis tuaj yeem zoo li daunting, tab sis rhuav tshem nws mus rau hauv cov kauj ruam tswj tau ua rau cov txheej txheem tuaj yeem ua tau. Nov yog qhov koj tuaj yeem pib:

Xaiv cov khoom zoo

Xaiv cov ntaub ntawv zoo yog qhov tseem ceeb rau kev ua tiav cov ntim qis. Koj yuav tsum xav txog yam xws li daim ntawv thov npaj, pob nyiaj siv, thiab cov khoom siv uas xav tau. Kev koom tes nrog cov neeg muab khoom lossis cov chaw tsim khoom muaj peev xwm tuaj yeem pab koj txiav txim siab. Lawv tuaj yeem qhia koj hauv kev xaiv cov ntaub ntawv uas haum rau koj qhov kev xav tau tshwj xeeb thiab cov hom phiaj. Tsis tas li ntawd, xav txog kev cuam tshuam ib puag ncig thiab kev ruaj khov ntawm cov khoom koj xaiv. Los ntawm kev ua li ntawd, koj tsis tsuas yog txhim kho kev ua tau zoo thiab kav ntev ntawm koj cov khoom, tab sis kuj tseem pab txhawb rau kev tsim khoom niaj hnub uas tseem ceeb rau kev ruaj khov.

Nkag siab txog Cov Txheej Txheem Tooling

Cov txheej txheem cuab yeej yog ib feem tseem ceeb ntawm cov khoom ntim qis. Nws suav nrog kev tsim pwm uas ua rau koj cov khoom zoo. Nov yog yam koj yuav tsum paub:

Hom Pwm

Ntau hom pwm ua haujlwm rau ntau lub hom phiaj. Koj tuaj yeem siv aluminium pwm rau lawv cov nqi-zoo thiab lub sijhawm hloov pauv sai. Steel pwm, ntawm qhov tod tes, muaj kev ruaj khov thiab tsim nyog rau kev tsim ntau dua. Kev nkag siab txog hom pwm muaj pab koj xaiv qhov kev xaiv zoo tshaj plaws rau koj cov kev xav tau ntau lawm.

Kev txiav txim siab nqi

Cov nqi cuab yeej tuaj yeem sib txawv heev. Tsawg-ntim ntau lawm feem ntau suav nrog cov nqi qis dua piv rau cov txheej txheem ib txwm muaj. Txawm li cas los xij, nws yog ib qho tseem ceeb kom sib npaug tus nqi nrog qhov zoo. Kev nqis peev hauv cov cuab yeej zoo ua kom cov txiaj ntsig tau zoo thiab txo cov khoom pov tseg. Xav txog qhov cuam tshuam ntawm qhov loj me thiab qhov nyuaj ntawm lub voj voog lub sij hawm thiab cov nqi. Optimizing pwm tsim tuaj yeem ua rau lub sijhawm teeb tsa sai thiab txo cov nuj nqis.

Xaiv ib tus neeg tsim khoom ntseeg tau

Xaiv cov chaw tsim khoom txhim khu kev qha yog qhov tseem ceeb rau kev ua tiav cov ntim qis. Nov yog yuav ua li cas ntsuas cov neeg koom tes muaj peev xwm:

Kev ntsuas kev paub thiab kev txawj ntse

Saib rau cov tuam txhab lag luam uas muaj kev paub dhau los hauv cov khoom ntim qis. Lawv cov kev txawj ntse tuaj yeem pab txhim kho koj cov qauv tsim thiab txhim kho kev ua tau zoo. Tshawb xyuas lawv cov ntaub ntawv teev tseg thiab nug cov ntaub ntawv los xyuas kom lawv muaj kev txawj ntse thiab kev paub.

Kev soj ntsuam zoo thiab kev txhawb nqa

Kev ua tau zoo thiab kev txhawb nqa yog qhov tseem ceeb thaum xaiv cov chaw tsim khoom. Ntsuam xyuas lawv cov txheej txheem tswj kom zoo thiab xyuas kom lawv ua tau raws li cov qauv kev lag luam. Tsis tas li ntawd, xav txog qib kev txhawb nqa uas lawv muab. Lub chaw tsim khoom uas muab kev pabcuam zoo rau cov neeg siv khoom thiab kev txhawb nqa kev pabcuam tuaj yeem yog tus khub tseem ceeb hauv koj txoj kev tsim khoom.

Los ntawm kev ua raws li cov kauj ruam no, koj tuaj yeem tsim lub hauv paus ruaj khov rau koj qhov kev ua haujlwm qis qis. Txoj hauv kev no tsis tsuas yog pab koj tswj cov nqi xwb tab sis kuj ua kom yooj yim thiab zoo hauv koj cov txheej txheem tsim khoom.

Cov txiaj ntsig ntawm Tsawg-Volume Production-Injection Molding

Nqi-zoo

Thaum koj xaiv cov khoom ntim qis-txhaj tshuaj molding, koj coj mus rhaub rau hauv cov nqi tsim khoom lag luam. Tsis zoo li cov khoom lag luam siab ib txwm muaj, uas xav tau kev nqis peev ntau ntxiv, cov khoom ntim qis txo qis cov nqi no. Koj tuaj yeem tsim nyob qhov twg los ntawm ob peb puas mus rau ob peb txhiab units yam tsis tau ua txhaum lub txhab nyiaj. Txoj hauv kev no pab koj tswj koj cov peev nyiaj tau zoo dua, tshwj xeeb tshaj yog tias koj ua lag luam me lossis pib ua lag luam. Los ntawm kev txo cov nqi siv cuab yeej thiab zam cov khoom lag luam loj, koj txuag nyiaj thiab txo kev pheej hmoo nyiaj txiag.

Ceev thiab Flexibility

Tsawg-volume ntau lawm-txhaj tshuaj molding muab koj unmatched ceev thiab yooj. Koj tuaj yeem teb sai sai rau kev hloov pauv kev lag luam thiab cov neeg siv khoom xav tau. Txoj kev no tso cai rau koj coj cov khoom lag luam sai dua li cov txheej txheem ib txwm muaj. Koj tuaj yeem yooj yim tsim kev hloov kho yam tsis muaj kev ncua ntev cuam tshuam nrog cov khoom ntim siab. Txawm hais tias koj tab tom sim cov qauv tsim tshiab lossis kev noj qab haus huv rau kev lag luam niche, txoj hauv kev no ua rau koj muaj peev xwm nyob ua ntej ntawm kev sib tw. Koj tuaj yeem hloov kho sai, ua kom koj cov khoom ua tau raws li cov neeg siv khoom xav tau.

Customization Opportunities

Customization yog ib qho txiaj ntsig tseem ceeb ntawm cov khoom ntim qis-txhaj tshuaj molding. Koj tuaj yeem tsim cov khoom tshwj xeeb uas haum rau cov neeg siv khoom tshwj xeeb. Txoj kev no txhawb kev tsim cov khoom me me, ua rau nws zoo tagnrho rau cov khoom siv tsawg lossis cov khoom tshwj xeeb. Koj muaj kev ywj pheej los sim nrog cov qauv tsim thiab cov khoom sib txawv, muab cov kev daws teeb meem rau koj cov neeg siv khoom. Los ntawm embracing customization, koj txhim khu koj hom kev thov thiab sib txawv koj tus kheej hauv kev ua lag luam. Qhov kev hloov pauv no tso cai rau koj los tshawb nrhiav cov tswv yim tshiab thiab tsim kho tshiab tsis tu ncua.

Cov kev sib tw los xav txog hauv Kev Tsim Khoom Tsawg

Tus nqi pib

Thaum koj pib nrog cov khoom ntim qis, koj yuav ntsib qee tus nqi pib. Cov nuj nqis no tuaj yeem suav nrog cov cuab yeej thiab cov nqi teeb tsa. Txawm hais tias cov nqi no feem ntau qis dua cov kev tsim khoom loj, lawv tseem tuaj yeem yog qhov tseem ceeb rau cov lag luam me. Koj yuav tsum tau ua tib zoo npaj nyiaj txiag thiab npaj rau cov kev nqis peev ua ntej no. Los ntawm kev ua li ntawd, koj tuaj yeem ua kom ntseeg tau tias koj cov txheej txheem tsim khoom ua haujlwm zoo yam tsis muaj kev cia siab txog nyiaj txiag teeb meem.

Yuav tsum muaj kev txawj ntse

Tsawg-volume ntau lawm-txhaj tshuaj molding yuav tsum muaj ib theem ntawm kev txawj ntse. Koj yuav tsum to taub qhov intricacies ntawm cov txheej txheem molding, xaiv cov khoom, thiab cov cuab yeej tsim. Yog tias koj tsis muaj kev txawj ntse no, xav txog kev koom tes nrog cov kws tshaj lij lossis cov tuam txhab tsim khoom. Lawv tuaj yeem coj koj los ntawm cov txheej txheem thiab pab koj kom tsis txhob raug nqi ntau. Kev nqis peev hauv kev cob qhia lossis ntiav cov neeg ua haujlwm txawj tuaj yeem txhim kho koj lub peev xwm tsim khoom thiab ua kom cov txiaj ntsig zoo.

Kev txwv nyob rau hauv ntau lawm Volume

Tsawg-ntim ntau lawm yog qhov zoo tagnrho rau cov khoom me me, tab sis nws muaj nws cov kev txwv. Tej zaum koj yuav pom tias nws nyuaj kom nce nrawm yog tias qhov kev thov nce ntxiv. Txoj kev no haum rau cov lag luam nrog cov khoom lag luam qis dua lossis cov uas nyob rau hauv kev loj hlob mus tas li. Txawm li cas los xij, yog tias koj cia siab tias yuav muaj kev loj hlob sai, koj yuav tsum npaj rau cov teeb meem scalability. Xav txog yuav ua li cas koj tuaj yeem hloov mus rau cov khoom ntim ntau dua yog tias xav tau. Los ntawm kev ua kom muaj zog, koj tuaj yeem hloov kho rau kev hloov pauv hauv kev lag luam thiab ua tau raws li cov neeg siv khoom xav tau zoo.

Cov tswv yim tswv yim rau kev ua tiav

Kev pib ntawm cov khoom ntim qis tuaj yeem yog txoj kev muaj txiaj ntsig zoo rau koj txoj kev lag luam. Txhawm rau kom ua tiav, xav txog cov tswv yim no uas yuav coj koj mus txog qhov txheej txheem.

Koom tes nrog cov kws tshaj lij kev tsim khoom

Xaiv tus tsim khoom tsim nyog yog qhov tseem ceeb. Koj xav tau ib tus neeg uas paub qhov ins thiab outs ntawm cov khoom ntim qis. Cov kws tshaj lij kev tsim khoom tuaj yeem pab koj taug qab cov txheej txheem nyuaj. Lawv coj cov kev pom muaj txiaj ntsig zoo rau kev txhim kho cov qauv tsim thiab txhim kho kev ua haujlwm. Nrhiav cov neeg koom tes nrog cov ntaub ntawv pov thawj hauv koj qhov kev lag luam. Nug rau cov ntaub ntawv siv thiab tshawb xyuas lawv cov haujlwm yav dhau los. Cov kauj ruam no ua kom koj koom tes nrog ib tus neeg uas nkag siab txog koj cov kev xav tau thiab tuaj yeem xa cov txiaj ntsig zoo.

Kev nqis peev hauv Cov Cuab Yeej Zoo

Cov cuab yeej zoo yog lub hauv paus ntawm kev ua tiav cov khoom ntim qis. Tej zaum nws yuav zoo li ntxias kom txiav cov nqi ntawm no, tab sis kev nqis peev hauv cov pwm zoo tau them nyiaj rau lub sijhawm ntev. Cov cuab yeej zoo ua kom muaj tseeb thiab txo cov khoom pov tseg. Nws kuj txo qhov kev pheej hmoo ntawm qhov tsis xws luag, txuag koj lub sijhawm thiab nyiaj txiag. Xav txog hom pwm uas haum koj cov kev xav tau ntau lawm. Aluminium pwm muab cov nqi-zoo thiab lub sijhawm hloov pauv sai, thaum cov pwm steel muab cov kav ntev rau cov qauv tsim. Los ntawm kev xaiv cov cuab yeej tsim nyog, koj teeb tsa theem rau kev tsim khoom zoo thiab txhim khu kev qha.

Kev Kawm Txuas Ntxiv thiab Kev Hloov Kho

Kev tsim toj roob hauv pes niaj hnub hloov zuj zus. Nyob ua ntej yuav tsum tau kawm tas li thiab yoog raws. Ua raws li kev lag luam tiam sis thiab kev nce qib ntawm kev siv technology. Mus koom kev cob qhia, webinars, thiab kev ua lag luam nthuav qhia kom nthuav koj txoj kev paub. Koom nrog cov kws tshaj lij kev lag luam thiab cov phooj ywg sib pauv tswv yim thiab kev paub dhau los. Ua raws li kev xav ntawm kev txhim kho tas mus li. Txoj hauv kev no yuav pab koj kho koj cov txheej txheem thiab nyob twj ywm kev sib tw. Los ntawm kev yoog raws cov kev hloov pauv, koj ua kom koj lub lag luam tseem nrawm thiab ua raws li kev xav tau ntawm kev lag luam.

"Bridge tooling thiab pre-production runs yog ib qho tseem ceeb nyob rau hauv manufacturing. Lawv pab smoothly mus ntawm prototyping mus rau loj-scale ntau lawm." Qhov kev nkag siab no qhia txog qhov tseem ceeb ntawm kev npaj rau kev loj hlob thiab kev loj hlob.

Los ntawm kev ua raws li cov lus qhia no, koj tuaj yeem ua tiav siv cov khoom ntim qis hauv koj lub lag luam. Txoj hauv kev no tsis yog tsuas yog txhim kho koj lub peev xwm tsim khoom tab sis tseem ua haujlwm rau koj rau kev loj hlob yav tom ntej thiab kev tsim kho tshiab.

Muaj peev xwm rau Kev Loj Hlob thiab Kev Tsim Kho Tshiab

Tsawg-volume ntau lawm-txhaj tshuaj molding qhib lub sijhawm zoo siab rau kev loj hlob thiab kev tsim kho tshiab hauv koj lub lag luam. Los ntawm kev txais txoj hauv kev no, koj tuaj yeem tshawb nrhiav txoj hauv kev tshiab thiab nthuav koj lub qab ntug.

Expanding Product Lines

Tsawg-ntim ntau lawm tso cai rau koj kom muaj ntau haiv neeg koj cov khoom muag yam tsis tas yuav muaj kev nqis peev loj. Koj tuaj yeem sim nrog cov qauv tshiab thiab qhia cov khoom txwv tsis pub dhau rau koj cov kab ntawv. Qhov kev hloov pauv no tso cai rau koj ua raws li cov neeg siv khoom sib txawv thiab coj mus rhaub rau hauv kev lag luam niche. Piv txwv li, khoom kim heev hom nyiamLouis Vuittonsiv cov txheej txheem tsim khoom tsawg los tswj kom muaj kev sib cais thiab rov hais dua. Los ntawm kev nthuav koj cov khoom lag luam, koj tuaj yeem nyiam cov neeg tuaj saib dav dua thiab ua kom koj lub lag luam muaj nyob.

Nkag mus rau Kev Lag Luam Tshiab

Kev nkag mus rau hauv kev lag luam tshiab ua tau zoo dua nrog cov khoom ntim qis. Koj tuaj yeem sim cov dej tsis tau cog lus rau kev tsim khoom loj. Txoj hauv kev no yog qhov tshwj xeeb tshaj yog rau cov lag luam niche uas qhov kev thov yuav tsis pom zoo rau cov khoom ntim siab. Tuam txhab uas muag nyiamPorscheleverage low-volume techniques to produce their rarest and most tshwjx tsheb tsheb, ntes cov xim ntawm cov neeg siv khoom tshwj xeeb. Los ntawm kev nkag mus rau cov lag luam tshiab, koj tuaj yeem faib koj cov nyiaj tau los thiab txo kev cia siab ntawm ib lub lag luam.

Leveraging Customer Feedback

Cov neeg siv khoom tawm tswv yim yog ib qho cuab tam muaj txiaj ntsig hauv ntiaj teb ntawm cov khoom ntim qis. Koj tuaj yeem sau cov kev nkag siab ntawm koj cov neeg siv khoom thiab siv lawv los kho koj cov khoom. Cov txheej txheem rov ua dua no tso cai rau koj los txhim kho raws li kev paub hauv ntiaj teb tiag. Los ntawm kev koom tes nrog koj cov neeg siv khoom, koj tuaj yeem tsim kom muaj kev sib raug zoo thiab txhawb nqa hom kev ntseeg siab. Cov neeg tsim khoom siv cov txheej txheem ntim qis feem ntau ua qhov tseem ceeb ntawm qhov zoo thiab kev kho kom haum raws li cov neeg xav tau kev pab zoo. Los ntawm kev siv cov neeg siv khoom tawm tswv yim, koj tuaj yeem ua kom koj cov khoom ua raws li kev xav tau ntawm kev lag luam thiab nyob ua ntej ntawm kev sib tw.

Kev koom ua ke cov tswv yim no rau hauv koj tus qauv kev lag luam tuaj yeem ua rau muaj kev loj hlob thiab kev tsim kho tshiab. Tsawg-volume ntau lawm-txhaj tshuaj molding muab cov cuab yeej koj xav tau los tshawb nrhiav qhov muaj peev xwm tshiab thiab hloov pauv hloov pauv kev lag luam.

Tam sim no koj tau tshawb xyuas cov kauj ruam tseem ceeb thiab cov txiaj ntsig ntawm Low-Volume Production-Injection Molding. Cov txheej txheem tsim khoom no muab cov txiaj ntsig zoo thiab hloov pauv hloov pauv rau cov lag luam me tab tom nrhiav kev tsim kho tshiab thiab loj hlob. Los ntawm kev tuav txoj hauv kev no, koj tuaj yeem sim cov qauv tshiab, tsim cov khoom siv tsawg, thiab teb nrawm rau kev hloov pauv hauv kev lag luam. Kev npaj tswv yim thiab tsim kev sib koom tes zoo nrog cov tuam txhab paub txog yog qhov tseem ceeb rau kev ua tiav. Cov ntsiab lus no xyuas kom koj ua kom muaj peev xwm ntawm cov khoom ntim qis, ua rau txoj hauv kev rau kev loj hlob yav tom ntej thiab kev tsim kho tshiab hauv koj lub lag luam.