Cov Lus Qhia

1. Nkag siab txog cov hauv paus

2. Kev txiav txim siab tseem ceeb rau koj qhov project

3. Sib piv cov nqi: Txhaj Molding vs. 3D Printing

4. Ntau lawm ceev thiab ua tau zoo

5. Kev xaiv cov khoom siv thiab cov khoom siv ntev

6. Complexity thiab tsim Flexibility

7. Ua qhov kev xaiv zoo rau koj lub lag luam

8. Vim li cas thiaj xaiv Ningbo Tiehou Auto Parts rau koj qhov kev tsim khoom xav tau

9. Kev xaus: Dab tsi yog qhov haum rau koj qhov project?

Nkag siab txog Cov Ntsiab Cai

Thaum txiav txim siab ntawm kev txhaj tshuaj molding thiab 3D luam ntawv rau koj qhov project tom ntej, nws yog ib qho tseem ceeb kom nkag siab txog qhov zoo thiab qhov tsis zoo ntawm txhua txoj kev tsim khoom. Ob lub thev naus laus zis tau hloov pauv cov txheej txheem tsim khoom, tab sis lawv qhov tsim nyog sib txawv nyob ntawm seb koj qhov project tshwj xeeb yuav tsum tau ua.

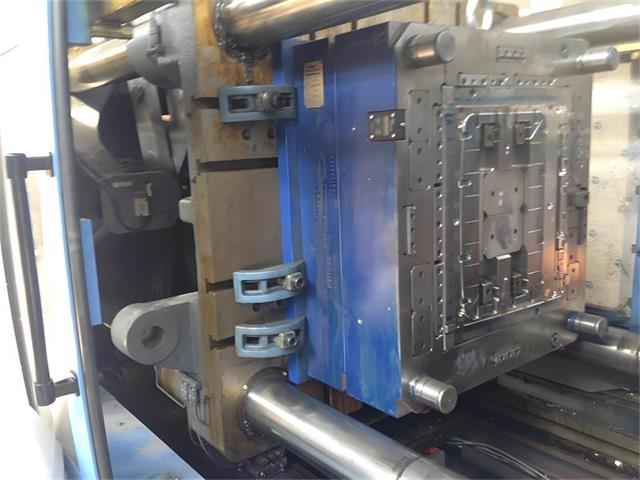

Txhaj Moldingyog ib qho kev sim-thiab-qhov tseeb raug txheej txheem, tshwj xeeb tshaj yog zoo-tsim rau high-volume ntau lawm. Nws koom nrog kev tsim pwm, feem ntau yog los ntawm cov hlau, rau hauv cov khoom siv molten - feem ntau yog yas lossis roj hmab - yog txhaj. Thaum txias, lub pwm qhib kom pom ib qho zoo kawg nkaus tsim. Kev txhaj tshuaj molding yog paub txog kev tsim cov khoom zoo sib xws, zoo tshaj plaws, tshwj xeeb tshaj yog rau kev lag luam uas xav tau qhov tseeb thiab ua haujlwm ntev, xws li tsheb, cov khoom siv, thiab cov khoom lag luam.

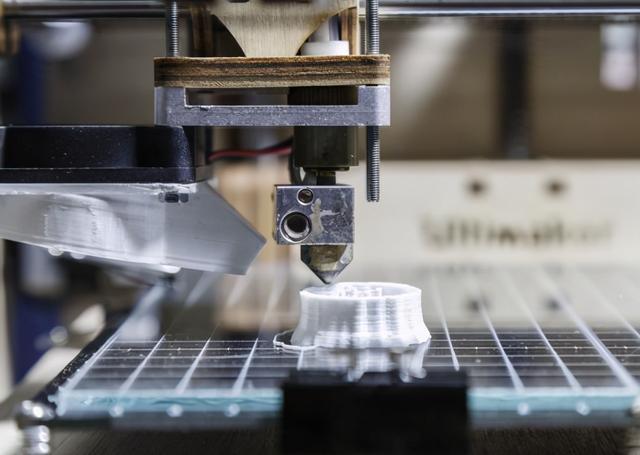

3D luam ntawv, ntawm qhov tod tes, yog cov thev naus laus zis tshiab uas tsim cov txheej txheem los ntawm txheej siv cov ntaub ntawv xws li yas, resin, lossis hlau. Nws muaj cov qauv tsim tsis sib xws thiab yog qhov zoo tagnrho rau kev tsim qauv, kev cai qhov chaw, thiab cov khoom ntim qis. 3D luam ntawv tso cai rau cov qauv tsim tsis yooj yim uas yuav ua tsis tau lossis kim dhau los ua tiav nrog cov qauv tsim khoom.

Cov ntsiab lus tseem ceeb rau koj qhov project

Txhawm rau kom ntseeg tau tias koj txoj haujlwm ua tiav, nws yog qhov tseem ceeb uas yuav tsum xav txog cov hauv qab no thaum xaiv ntawm kev txhaj tshuaj molding thiab 3D luam ntawv:

- Ntau lawm ntim:Koj xav tau pes tsawg units?

- Part complexity:Koj tus qauv tsim puas suav nrog cov ntsiab lus sib txawv lossis cov duab geometry nyuaj?

- Cov ntaub ntawv xav tau:Cov ntaub ntawv twg yog qhov zoo tshaj plaws rau koj daim ntawv thov?

- Tus nqi:Koj pob nyiaj siv li cas rau ob qho tib si thawj zaug thiab kev tsim khoom ib chav?

- Lub sijhawm:Koj xav tau koj cov khoom xa tuaj sai npaum li cas?

Sib piv cov nqi: Txhaj Moulding vs. 3D Printing

Tus nqi feem ntau yog qhov kev txiav txim siab thaum xaiv txoj kev tsim khoom.

- Txhaj Molding:Thaum tus nqi pib ntawm kev tsim pwm tuaj yeem siab, tus nqi ib-unit poob qis dua nrog cov khoom ntim ntau dua. Qhov no ua rau kev txhaj tshuaj molding tus nqi-zoo rau kev tsim khoom loj, qhov twg ntau txhiab lossis lab ntawm qhov xav tau.

- 3D luam ntawv:Tsis xav tau cov pwm kim, 3D luam ntawv feem ntau yog siv nyiaj ntau dua rau cov khoom ntim qis lossis kev tsim qauv. Txawm li cas los xij, tus nqi ntawm ib chav tsev tseem tseem siab dua piv rau kev txhaj tshuaj molding, tshwj xeeb tshaj yog raws li kev tsim khoom nce.

Kev txiav txim siab tus nqi piv txwv:

Yog tias koj qhov project xav tau 10,000 ntu,txhaj tshuaj moldingNws yuav yog qhov kev xaiv pheej yig dua vim nws tus nqi qis dua ib chav. Txawm li cas los xij, yog tias koj tsuas yog tsim 100 qhov chaw,3D luam ntawvtej zaum yuav tsim nyog raws li nws zam qhov siab upfront nqi ntawm pwm tsim.

Ntau lawm ceev thiab Efficiency

Lwm qhov tseem ceeb tshaj plaws yog qhov ceev thiab kev ua haujlwm ntawm kev tsim khoom.

- Txhaj Molding: Thaum cov pwm tsim, kev txhaj tshuaj molding tuaj yeem tsim cov khoom ntawm tus nqi siab heev - qee zaum ntau txhiab qhov hauv ib teev. Qhov no ua rau nws zoo tagnrho rau cov ntim ntim ntau lawm nrog cov sijhawm kaw.

- 3D luam ntawv: Thaum 3D luam ntawv muaj lub sijhawm teeb tsa sai dua (tsis xav tau pwm), kev tsim khoom nrawm dua, tshwj xeeb tshaj yog rau cov khoom loj. Nws ua tau zoo nyob rau hauv cov xwm txheej uas yuav tsum tau ua sai sai lossis cov khoom me me, tab sis yuav tsis haum rau kev tsim khoom loj.

Efficiency Piv txwv:

Yog tias koj tab tom ua haujlwm ntawm tus qauv tsim khoom tshiab thiab xav tau cov qauv nrawm rau kev sim thiab kho kom zoo,3D luam ntawvmuab qhov yooj rau iterate sai. Txawm li cas los xij, rau kev tsim khoom kawg,txhaj tshuaj moldingfeem ntau yog nrawm dua thiab ua haujlwm zoo dua.

Kev xaiv cov khoom siv thiab cov khoom siv ntev

Xaiv cov khoom tsim nyog yog qhov tseem ceeb rau kev ua kom lub zog thiab kev ua haujlwm ntawm koj cov khoom.

- Txhaj Molding: Muaj ntau yam khoom siv, suav nrog ntau yam yas, roj hmab, thiab qee yam hlau. Cov ntaub ntawv siv hauv kev txhaj tshuaj molding feem ntau yog siv tau ntev dua thiab zoo dua rau cov khoom siv kawg uas yuav tsum tau muaj zog, yoog raws, lossis ua haujlwm rau cov tshuaj thiab cua sov.

- 3D luam ntawv: Txawm hais tias cov khoom siv ntau yam muaj rau 3D luam ntawv tau nthuav dav, nws tseem poob qab kev txhaj tshuaj molding raws li cov khoom siv ntau yam thiab ua haujlwm ntev. 3D tshuab luam ntawv feem ntau yog siv rau cov qauv los yog cov ntawv kev cai es tsis yog kev ntxhov siab, kev siv mus sij hawm ntev.

Khoom siv piv txwv:

Rau ib feem ntawm lub tsheb uas yuav tsum tau tiv taus qhov kub thiab txias thiab mechanical stress,txhaj tshuaj moldingsiv cov yas lossis roj hmab uas muaj kev ua haujlwm siab yog qhov kev xaiv zoo tshaj plaws. Rau ib qho kev cai, tsawg-ntim ib feem nrog cov ntsiab lus intricate,3D luam ntawvtej zaum yuav yog txoj kev mus.

Complexity thiab tsim Flexibility

Qhov nyuaj ntawm koj tus qauv tsim thiab qhov yooj yim xav tau kuj tuaj yeem cuam tshuam koj qhov kev xaiv.

- Txhaj Molding: Qhov zoo tshaj plaws haum rau cov qauv tsim uas yuav ua rau ntau qhov ntau. Thaum nws tuaj yeem ua raws li cov duab geometry nyuaj, qhov kev tsim thawj zaug yuav tsum tau ua tib zoo xav txog vim tus nqi siab ntawm pwm tsim.

- 3D luam ntawv: Excels nyob rau hauv kev tsim complex, intricate designs uas yuav tsis yooj yim sua los yog raug txwv tsis pub muaj kev txhaj tshuaj molding. Qhov no ua rau nws yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv, cov qauv, lossis cov khoom siv me me uas tsim kev yooj yim yog qhov tseem ceeb.

Tsim Flexibility Piv txwv:

Yog tias koj qhov project cuam tshuam nrog cov qauv tsim nrog cov kab noj hniav sab hauv lossis cov ntsiab lus tsis sib xws,3D luam ntawvtso cai rau koj kom ua tiav cov no yam tsis tas yuav tsum tau ua cov pwm uas kim thiab nyuaj. Rau qhov yooj yim, siab ntim qhov chaw,txhaj tshuaj moldingtseem yog txoj kev nyiam.

Ua Kev Xaiv Zoo rau Koj Kev Lag Luam

Txhawm rau kom paub tseeb tias koj xaiv txoj kev tsim khoom tsim nyog, nws yog ib qho tseem ceeb uas yuav tsum ntsuas cov yam ntxwv saum toj no tiv thaiv koj qhov kev xav tau tshwj xeeb. Kev nkag siab txog qhov sib txawv no tuaj yeem ua rau muaj kev cuam tshuam loj rau koj txoj haujlwm ua tiav, kom ntseeg tau tias koj tau txais cov khoom zoo hauv koj cov peev nyiaj thiab lub sijhawm.

Vim li cas thiaj xaiv Ningbo Teko Auto Parts rau koj qhov kev xav tau tsim khoom

Ntawm Ningbo Teko Auto Parts Co., Ltd, peb tshwj xeeb hauv cov pwm kev cai, yas, roj hmab, thiab cov khoom siv kho vajtse, catering rau kev lag luam xws li tsheb, kev tsim kho, cov khoom siv, thiab lwm yam. Peb nkag siab tias txhua qhov project yog qhov tshwj xeeb, thiab peb pab neeg muaj kev paub dhau los nyob ntawm no los pab koj xaiv txoj kev tsim khoom tsim nyog rau koj cov kev xav tau.

Peb xyuas kom meej tias koj qhov project tau txais txiaj ntsig los ntawm qhov zoo tshaj plaws ntawm ob lub ntiaj teb - txawm tias nws yog qhov tseeb thiab kev ua haujlwm ntawm kev txhaj tshuaj molding lossis kev tsim qauv yooj yim ntawm 3D luam ntawv. Peb lub hom phiaj yog xa cov khoom uas ua tau raws li koj cov lus qhia meej, raws sijhawm, thiab hauv pob nyiaj siv.

Lus Nug: Dab tsi yog qhov haum rau koj qhov project?

Thaum txiav txim siab ntawm kev txhaj tshuaj molding thiab 3D luam ntawv, xav txog koj qhov project ntim, tsim complexity, cov khoom xav tau, thiab pob nyiaj siv. Ob txoj kev muaj lawv lub zog, thiab qhov kev xaiv zoo tshaj plaws nyob ntawm koj qhov kev xav tau tshwj xeeb.

Yog tias koj tsis paub meej tias txoj kev twg yog qhov zoo rau koj, hu rau peb pab neeg ntawm Ningbo Teko Auto Parts. Peb nyob ntawm no los pab koj kom paub tseeb tias koj qhov project ua tiav, txawm tias nws yog los ntawm kev txhaj tshuaj molding, 3D luam ntawv, lossis ob qho tib si ua ke.

Hu rau peb hnub no los tham txog koj qhov project xav tau thiab nrhiav kev daws teeb meem zoo tshaj plaws rau koj cov kev xav tau tsim khoom. Peb cog lus tias yuav xa cov khoom zoo, kev cai uas pab koj ua tiav.