Nyob rau hauv lub ntiaj teb no ntawm kev tsim yas, ntxig molding thiab overmolding yog ob txoj kev nrov uas muaj qhov tshwj xeeb zoo rau kev tsim cov khoom siv, kev ua haujlwm siab. Kev nkag siab qhov sib txawv ntawm cov txheej txheem no tuaj yeem pab koj txiav txim siab paub txog koj cov haujlwm thiab siv peb cov kev pabcuam tshwj xeeb txhaj tshuaj molding.

Dab tsi yog Insert Molding?

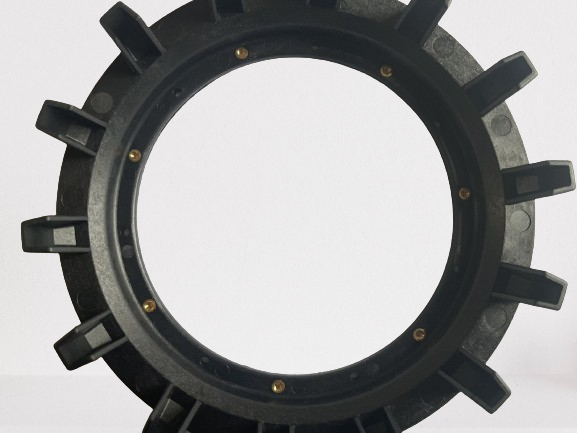

Ntxig molding yuav tsum tso ib qho preformed tivthaiv, feem ntau hlau, rau hauv lub pwm kab noj hniav ua ntej txhaj cov yas nyob ib ncig ntawm nws. Qhov tshwm sim yog ib qho, kev sib xyaw ua ke uas sib xyaw ua ke ntawm ob qho tib si cov khoom siv. Cov txheej txheem no feem ntau siv rau:

• Hlau fasteners nyob rau hauv cov khoom yas

• Cov khoom siv hluav taws xob

• Threaded inserts

Cov txiaj ntsig tseem ceeb ntawm Insert Molding:

• Ua kom muaj zog thiab kav ntev:Los ntawm kev sib xyaw hlau ntxig, qhov ua tau zoo muaj cov khoom siv zoo tshaj plaws.

• Txhim kho los ua ke Efficiency:Ua ke ntau yam khoom rau hauv ib qho molded ib feem, txo cov sij hawm sib dhos thiab tus nqi.

• Kev tsim kom yooj yim dua:Tso cai rau kev sib xyaw ua ke ntawm cov khoom sib txawv, txhim kho kev ua haujlwm ntawm cov khoom kawg.

Overmolding yog dab tsi?

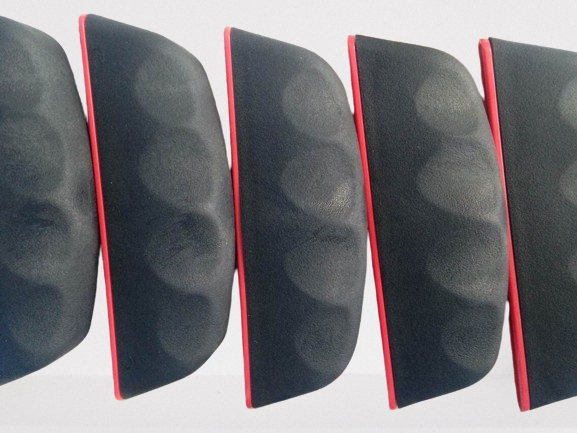

Overmolding yog txheej txheem ob-kauj ruam uas cov khoom siv hauv paus (feem ntau yog cov yas nruj) yog molded ua ntej, ua raws li qhov thib ob, cov khoom softer (xws li silicone los yog TPU) molded tshaj thawj. Cov txheej txheem no feem ntau yog siv rau:

• Soft-kov tuav ntawm cov cuab yeej

• Cov ntsaws ruaj ruaj thiab gaskets

• Cov khoom siv ntau yam

Cov txiaj ntsig tseem ceeb ntawm Overmolding:

• Txhim kho cov neeg siv kev nplij siab thiab zoo nkauj:Muab qhov chaw mos-kov lossis ergonomic nta, txhim kho cov neeg siv kev paub.

• Txhim kho cov khoom ua haujlwm:Muab cov ntaub ntawv sib txawv los txhim kho cov khoom ua tau zoo, xws li ntxiv cov roj hmab hla cov yas kom tuav tau zoo dua.

• Tus nqi tsim khoom:Txo qhov xav tau rau cov kauj ruam sib dhos ntxiv los ntawm kev sib txuas ntau yam khoom hauv ib txheej txheem.

Sib piv Insert Molding thiab Overmolding

| Yam | Ntxig Moulding | Overmolding |

| Txheej txheem | Embeds pre-formed insert nyob rau hauv lub yas ib feem. | Moulds ib qho khoom thib ob tshaj ib feem yav dhau los molded. |

| Daim ntawv thov | Hlau-yas Cheebtsam, threaded qhov chaw, connectors. | Ergonomic grips, ntau yam khoom siv, qhov chaw mos-kov. |

| Qhov zoo | Txhim kho durability, txo kev sib dhos, hloov tau yooj yim. | Txhim kho kev nplij siab thiab zoo nkauj, txhim kho kev ua haujlwm, txuag nqi. |

| Kev sib tw | Yuav tsum tau muab tso rau ntawm cov ntxig ntxig. | Tswj kev sib raug zoo ntawm cov khoom sib txawv. |

Xaiv cov txheej txheem zoo rau koj qhov project

Thaum txiav txim siab ntawm insert molding thiab overmolding, xav txog cov hauv qab no:

• Material Compatibility:Xyuas kom cov ntaub ntawv siv nyob rau hauv ob qho tib si txheej txheem yog sib xws thiab yuav sib raug zoo.

• Kev Tsim Nyog:Ntsuam xyuas qhov tsim complexity thiab functionality xav tau rau koj cov khoom kawg.

• Nqi thiab Efficiency:Xav txog qhov cuam tshuam tus nqi thiab kev txuag nyiaj los ntawm kev txo cov kauj ruam sib dhos.

Vim li cas thiaj xaiv TEKO rau Koj Qhov Kev Txhaj Tshuaj Molding?

Ntawm TEKO, peb tshwj xeeb hauv ob qho tib si ntxig molding thiab overmolding cov txheej txheem, muab cov kev daws teeb meem raws li koj cov kev xav tau tshwj xeeb. Peb cov kws tshaj lij hauv cov txheej txheem molding siab heev ua kom cov khoom zoo, cov khoom siv ruaj khov uas txhim kho koj qhov kev tsim kho tshiab.

Peb Muaj Peev Xwm:

• Custom Moulds:Ua raws li koj qhov kev qhia tshwj xeeb rau kev ua haujlwm zoo.

• Yas, Roj Hmab, thiab Hardware Parts:Versatile cov ntaub ntawv kom haum rau ntau yam kev siv.

• Kev Paub Txog Kev Lag Luam:Kev paub dav dav hauv tsheb, khoom siv, kev tsim kho, thiab lwm yam.

Tiv tauj peb Hnub no

Npaj los coj koj cov khoom tsim rau qib tom ntej? Tiv tauj peb ntawm TEKO los tham txog koj qhov project xav tau thiab nrhiav seb peb cov kev pabcuam txhaj tshuaj tuaj yeem pab tau koj li cas. Mus saib peb lub vev xaibTEKOkom paub ntau ntxiv thiab saib peb cov ntaub ntawv ntawm cov haujlwm ua tiav.

Hu rau Action:Koom tes nrog TEKO rau koj qhov project tom ntej thiab paub txog cov txiaj ntsig ntawm peb cov kws tshaj lij kev txhaj tshuaj molding cov kev pabcuam. Hu rau peb hnub no los thov kev tsocai lossis kev sib tham!