Precision txhaj molding plays lub luag haujlwm tseem ceeb hauv kev txhim kho kev tsim tsheb. Nws txhim kho kev ua tau zoo thiab kev ua tau zoo los ntawm kev tsim cov khoom sib sib zog nqus, zoo li aluminium extrusion profiles, uas ua rau kom muaj roj zoo dua. Tsis tas li ntawd, kev tsim khoom ntawmyas auto qhov chawlos ntawm cov txheej txheem tshiab no txo qis cov khoom pov tseg, muab cov kev daws teeb meem zoo uas muaj txiaj ntsig zoo rau cov tuam txhab thiab ib puag ncig. Tsis tas li ntawd, thev naus laus zis tuaj yeem siv los tsim cov khoom tshwj xeeb xws li cov duab plaub linear tso dej da dej thiab cov dej txias phaj tooj liab raj, qhia txog nws cov kev siv ntau yam hauv ntau daim ntawv thov.

Ntsiab Cai

- Precision txhaj molding txhim kho tsheb tsim los ntawm kev tsimsib sib zog nqus qhov chaw, txhim kho roj efficiency, thiab txo cov khoom pov tseg.

- Cov txheej txheem no muaj qhov tshwj xeeb tsim qauv yooj yim, tso cai rau cov duab nyuaj thiab kev sib koom ua ke ntawm cov khoom sib txawv hauv ib feem.

- Txais kev txhaj tshuaj molding ua rau kev txuag nqi tseem ceeb los ntawm kev txo cov khoom pov tseg thiab ua kom cov txheej txheem ntau lawm, ua rau nws tseem ceeb rau kev sib tw tsim khoom.

Cov txiaj ntsig ntawm Precision Txhaj Moulding

Precision txhaj tshuaj molding muaj ntau yam zoo uas txhim khu kev tsim tsheb. Los ntawm kev siv cov txheej txheem tshiab no, koj tuaj yeem ua tiav qhov kev txhim kho zoo kawg nkaus hauv kev tsim qauv yooj yim, cov khoom siv tau zoo, thiab kev siv nyiaj zoo.

Tsim Flexibility

Ib qho ntawm cov txiaj ntsig zoo ntawm kev txhaj tshuaj molding yog nws qhov tshwj xeebtsim yooj. Cov txheej txheem no tso cai rau koj los tsim cov geometries intricate thiab complex uas lwm txoj kev tsim khoom tawm tsam kom ua tiav. Nov yog qee qhov tseem ceeb ntawm kev tsim qauv yooj yim:

- Multi-shot molding thiab overmolding ua rau koj ua ke cov ntaub ntawv nyuaj thiab mos hauv ib qho khoom. Qhov no txhim kho kev ua haujlwm thiab kev nplij siab thaum txo cov kauj ruam sib dhos.

- Lub peev xwm los tsim cov duab nyuaj, xws li undercuts thiab nyias phab ntsa, qhib lub ntiaj teb ntawm kev tsim muaj peev xwm rau cov khoom siv tsheb.

- Advanced molding cov txheej txheem txhawb kev sib koom ua ke ntawm ntau yam ntaub ntawv, tso cai rau kev tsim kho tshiab uas ua tau raws li cov kev xav tau tshwj xeeb.

Nrog precision txhaj molding, koj tuaj yeem thawb cov ciam teb ntawm kev tsim tsheb, tsim cov khoom siv uas tsis yog tsuas yog ua haujlwm xwb tab sis kuj ua kom zoo nkauj.

Khoom siv tau zoo

Khoom siv efficiencyyog lwm qhov tseem ceeb ntawm kev txhaj tshuaj molding. Cov txheej txheem no txo qis cov khoom pov tseg thiab ua kom siv cov khoom siv raw, uas yog qhov tseem ceeb hauv kev lag luam niaj hnub no. Xav txog cov ntsiab lus hauv qab no:

- Cov tuam txhab feem ntau muaj kev txo qis ntawm 25-40% hauv cov khib nyiab thiab qhov tsis xws luag thaum siv precision molding. Qhov no txhais tau tias koj tuaj yeem tsim ntau qhov chaw nrog cov khoom siv tsawg.

- Qhov nruab nrab, 98% ntawm cov khoom siv raw khoom yog siv rau hauv cov khoom kawg los ntawm txoj kev no. Qhov kev ua tau zoo ntawm qib siab no txhais tau rau kev txuag nqi tseem ceeb.

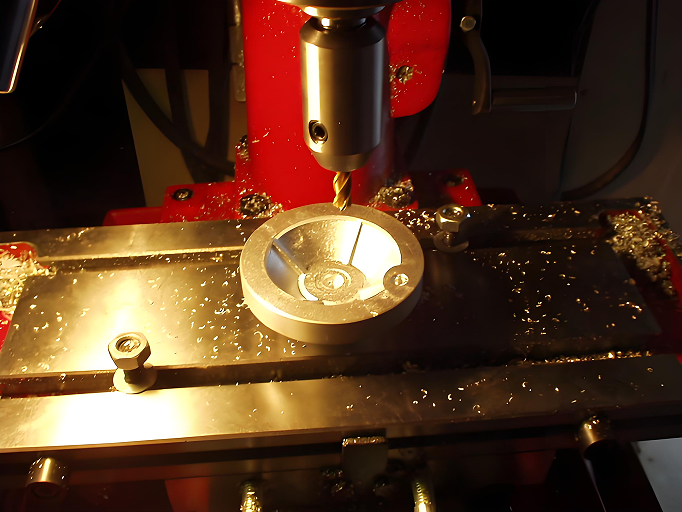

- Cov txheej txheem cuam tshuam nrog melting yas resin, txhaj rau hauv cov pwm precision-machined, thiab txias nws los tsim cov khoom siv tsheb. Qhov no ua kom koj ua tiav qib siab ntawm kev nthuav dav thiab raug, tseem ceeb heev rau cov khoom sib txawv xws li dashboards thiab qhov rooj vaj huam sib luag.

Los ntawm kev siv precision txhaj tshuaj molding, koj tsis tsuas yog txhim kho qhov zoo ntawm koj cov khoom siv tsheb, tab sis kuj tseem pab txhawb kev ruaj ntseg los ntawm kev txo cov khoom pov tseg.

Nqi-zoo

Tus nqi-kev ua tau zoo yog qhov tseem ceeb rau kev txiav txim siab rau txhua qhov chaw tsim tsheb. Precision txhaj molding ua tau zoo nyob rau hauv cheeb tsam no los ntawm kev txo cov khoom pov tseg thiab optimizing cov txheej txheem ntau lawm. Nov yog li cas:

- Cov ntim ntau lawm txo qis tus nqi ntawm ib chav los ntawm kev nthuav tawm cov nqi pib pib dua ntau qhov chaw. Qhov no ua rau nws yooj yim rau cov khoom loj.

- Cov thev naus laus zis zoo li CAD txhim kho cov txheej txheem tsim, txhim kho cov khoom siv thiab txo cov nqi tsim khoom tag nrho.

- Cov txheej txheem tso cai rau kev siv cov ntaub ntawv zoo, ua rau kev txuag cov khoom tseem ceeb.

Tsis tas li ntawd, cov txiaj ntsig ntev ntawm kev siv cov kev txhaj tshuaj molding muaj xws li kev ua haujlwm siab thiab ceev, cov txiaj ntsig zoo, thiab kev lag luam ntawm cov nplai. Cov xwm txheej no ua ke ua rau muaj txiaj ntsig zoo ntawm kev tsim khoom, kom ntseeg tau tias koj tseem muaj kev sib tw hauv kev lag luam tsheb.

Los ntawm embracing precision txhaj molding, koj tuaj yeem ua tiav qhov sib npaug ntawm qhov zoo, kev ua tau zoo, thiab kev txuag nqi, ua rau nws yog ib qho khoom siv tsis tseem ceeb hauv kev tsim tsheb niaj hnub.

Kev siv hauv Automotive Cheebtsam

Precision txhaj molding plays lub luag haujlwm tseem ceeb hauv kev tsim ntau yam khoom siv tsheb. Cov txheej txheem no txhim kho cov kev ua tau zoo, durability, thiab zoo nkauj txaus siab ntawm qhov chaw thoob plaws ntau qhov chaw ntawm kev tsim tsheb. Cia peb tshawb xyuas seb qhov kev txhaj tshuaj molding zoo li cas rau cov khoom siv cav, cov khoom siv sab hauv, thiab cov vaj huam sib luag sab nrauv.

Cav Qhov Chaw

Lub cav Cheebtsam tau txais txiaj ntsig zoo los ntawm kev txhaj tshuaj molding. Txoj kev no tso cai rau koj los tsim cov khoom uas sib sib zog nqus tsis tau ruaj khov, uas yog qhov tseem ceeb rau kev txhim kho kev ua haujlwm ntawm lub tsheb thiab kev siv roj. Feem ntau tsim cov cav tov muaj xws li:

- Cua intake manifolds

- Valve npog

- Sensor vaj tse

- Hluav taws xob connectors

Siv cov khoom siv xws li polyamide (PA) thiab polyphenylene sulfide (PPS) kom ntseeg tau tias cov khoom no tiv taus qhov kub thiab txias thiab ua haujlwm hnyav. Qhov zoo ntawm kev siv cov yas rau lub cav muaj xws li:

- Txo qhov hnyav: Cov khoom sib sib zog nqus txhim kho kev ua haujlwm ntawm lub tsheb tag nrho.

- Durability: Precision txhaj molding txhim khu lub zog thiab kev ntseeg siab ntawm qhov chaw, ua rau lawv tsim nyog hloov cov khoom siv hlau.

| Tau txais txiaj ntsig | Kev piav qhia |

|---|---|

| Cov khoom siv ua haujlwm siab | Siv cov thermoplastics uas tiv taus ib puag ncig hnyav, txhim kho lub zog thiab kev ntseeg siab. |

| Cov qauv tsim | Tso cai rau kev tsim cov khoom sib txuam nrog nruj tolerances, kom ntseeg tau zoo ib yam. |

| Hloov cov khoom siv hlau | Muaj peev xwm ua tau qhov chaw uas tuaj yeem hloov cov hlau, ua rau muaj kev ruaj ntseg tag nrho. |

Sab hauv Cheebtsam

Precision txhaj molding kuj revolutionizes zus tau tej cov automotive Cheebtsam sab hauv. Cov txheej txheem no tso cai rau kev tsim cov geometry nyuaj thiab kev tsim qauv sib xyaw ua ke uas txhim kho kev ua haujlwm thiab zoo nkauj. Cov khoom tseem ceeb sab hauv uas tsim los ntawm txoj kev no suav nrog:

- Dashboards

- Qhov rooj panels

- Clips thiab fasteners

Cov txiaj ntsig ntawm kev txhaj tshuaj molding rau cov khoom no yog qhov tseem ceeb:

| Hom Lub Npe | Cov txiaj ntsig ntawm Txhaj Molding |

|---|---|

| Dashboards | Complex duab, durability, aesthetic thov |

| Qhov Rooj Vaj Huam Sib Luag | High repeatability, lub zog |

| Clips thiab fasteners | Precision, sib xws hauv kev tsim khoom |

Ntxiv mus, precision txhaj tshuaj molding ua rau koj ua tiav kev ua tiav thiab kev cai xim uas phim lub tsheb tsim. Qhov no muaj peev xwm txhim kho qhov pom kev pom ntawm qhov chaw xws li kev cai trims thiab iav pob qhov rooj, ua rau lawv tsis tsuas yog ua haujlwm tab sis kuj txaus nyiam.

Sab nrauv Panels

Thaum nws los txog rau sab nrauv panels, precision txhaj molding muaj qhov zoo tshaj plaws. Cov txheej txheem no tso cai rau kev tsim cov khoom sib sib zog nqus uas txhim kho aerodynamic efficiency thiab pom kev rov hais dua. Cov txiaj ntsig tseem ceeb suav nrog:

- High precision nyob rau hauv tsim complex duab, qhov tseem ceeb rau intricate automotive Cheebtsam.

- Lub peev xwm los tsim lub teeb yuag sab nrauv vaj huam sib luag uas txhim khu kev ua haujlwm ntawm lub tsheb tag nrho.

- Aesthetic txhim kho los ntawm kev ua tiav du thiab cov ntsiab lus sib txawv.

Lub versatility ntawm kev txhaj tshuaj molding txhawb cov khoom siv tes ua ntawm cov khoom uas ua tau raws li qhov xav tau ntawm kev ua haujlwm zoo thiab zoo nkauj. Qhov no ua kom cov vaj huam sib luag sab nrauv tsis yog tsuas yog ua tau zoo xwb tab sis kuj tseem ua rau lub tsheb tsim tag nrho.

Case Studies of Successful Implementations

Ningbo Tiehou Auto Parts Co., Ltd

Ningbo Tiehou Auto Parts Co., Ltd. piv txwv kev tsim kho tshiab hauvprecision txhaj moldingnyob rau hauv lub automotive sector. Tsim los ntawm 2018, lub tuam txhab no muaj ntau tshaj 20 xyoo ntawm kev paub hauv kev ua haujlwm. Lawv txoj kev mob siab rau kev tsim thiab kev tsim khoom zoo tau ua rau kev txhim kho cov khoom zoo rau ntau yam kev siv tsheb.

Lawv tsom mus rau kev ruaj khov thiab cov kev daws teeb meem rau cov neeg siv khoom tau ua rau muaj kev nce qib tseem ceeb. Piv txwv li, lawv tau ua tiav kev koom ua kekev txhaj tshuaj molding txheej txheemlos tsim cov khoom sib txuam uas sib xyaw cov khoom sib txawv. Qhov kev tsim kho tshiab no tsis tsuas yog txhim kho kev ua haujlwm tab sis kuj txo lub sijhawm sib dhos, ua rau cov txheej txheem tsim tau zoo dua.

Aluminium Extrusion Profiles hauv Kev Ua

Aluminium extrusion profiles ua lub luag haujlwm tseem ceeb hauv kev txo cov tsheb hnyav thaum tuav lub zog. Cov profiles no muaj qhov sib zog-rau-qhov hnyav, ua rau lawv zoo tagnrho rau cov khoom tseem ceeb ntawm lub tsheb. Nov yog qee qhov txiaj ntsig tseem ceeb:

- Hloov lub tsheb lub cev-hauv-dawb (BIW) qauv los ntawm cov hlau mus rau txhuas tuaj yeem ua rau txo qhov hnyav li ntawm 40% hauv qhov hloov pauv.

- Cov khoom tshwj xeeb ntawm txhuas, xws li cov khoom siv hluav taws xob thiab lub zog, txhim khu nws daim ntawv thov hauv ntau yam khoom siv hauv tsheb.

- Cov khoom sib sib zog nqus zoo li cov kab teeb ci thiab cov ncej ncej pab txhawb kev txhim kho roj thiab kev ua haujlwm ntawm lub tsheb tag nrho.

Los ntawm kev siv aluminium extrusion profiles, manufacturers tuaj yeem ua tiav qhov hnyav hnyav, uas yog qhov tseem ceeb rau kev tsim tsheb niaj hnub.

Yav tom ntej Trends hauv Automotive Manufacturing

Raws li kev lag luam tsheb hloov zuj zus mus, precision txhaj tshuaj molding tseem ua lub luag haujlwm tseem ceeb hauv kev tsim cov qauv tsim khoom yav tom ntej. Koj tuaj yeem cia siab tias muaj kev nce qib tseem ceeb hauv cov ntaub ntawv thiab kev koom ua ke ntawm cov thev naus laus zis los txhim kho kev tsim khoom thiab kev ruaj ntseg.

Kev nce qib hauv cov khoom siv

Automotive sector tau pom qhov nce ntxiv hauv cov ntaub ntawv tshiab uas ua kom zoo dua qub thiab txo qhov cuam tshuam ib puag ncig. Nov yog qee qhov kev txhim kho tseem ceeb:

- Hybrid Cheebtsam: Cov no muab cov yas thiab hlau, optimizing lub zog thaum txo qhov hnyav.

- Carbon Fiber Composites: Lawv muab cov kev daws teeb meem uas txhim khu kev ua haujlwm ntawm roj thiab txo cov emissions.

- Advanced High-Strength Steels (AHSS): Cov ntaub ntawv no muaj lub zog zoo dua, tso cai rau kev txo qhov hnyav yam tsis muaj kev cuam tshuam kev ua haujlwm.

- Bio-based thiab Recycled Plastics: Cov kev hloov hauv eco-phooj ywg pab txo cov khoom pov tseg thiab cov nqi tsim khoom tsawg.

Kev ua lag luam rau cov khoom siv hluav taws xob txuas ntxiv mus ntxiv cov thermoplastics yog npaj kom loj hlob, uas qhia txog qhov kev thov muaj zog rau cov khoom siv sib zog uas ua tau raws li kev cai nruj ib puag ncig.

Kev koom ua ke nrog lwm yam technologies

Kev sib koom ua ke ntawm cov thev naus laus zis siab tshaj yog hloov pauv qhov kev txhaj tshuaj molding. Koj tuaj yeem cia siab tias yuav pom:

- Automation: Ua kom automation streamlines ntau lawm, txhim kho qhov tseeb thiab txo nqi zog.

- Artificial txawj ntse (AI): AI txhim kho cov txheej txheem tsim khoom, txhim kho kom zoo thiab txo cov khoom pov tseg. Nws siv high-frequency sensor cov ntaub ntawv rau qhov tsis xws luag thiab kev tswj cov txheej txheem.

- Kev Lag Luam 4.0 Cov Cai: Cov ntsiab cai no txhim kho cov txheej txheem tsim khoom, kom ntseeg tau tias koj ua tiav qhov tseeb hauv kev tsim tsheb.

| Technology | Kev cuam tshuam |

|---|---|

| Automation | Streamlines ntau lawm, txhim kho qhov tseeb, thiab txo cov nqi zog. |

| AI | Revolutionizes precision txhaj molding, txhim kho efficiency thiab zoo. |

| Kev lag luam 4.0 | Siv cov cuab yeej ntse los txhim kho cov txheej txheem tsim khoom hauv kev tsim tsheb. |

Los ntawm kev lees txais cov kev nce qib no, koj tuaj yeem txhim kho qhov ua tau zoo thiab kev ruaj khov ntawm kev tsim tsheb, tso koj cov qauv tsim rau yav tom ntej.

Precision txhaj molding yog qhov tseem ceeb rau kev tsim tsheb niaj hnub. Nws pab koj tsimsib sib zog nqus Cheebtsam, xws li aluminium extrusion profiles, uas txhim khu kev ua haujlwm ntawm lub tsheb. Cov txheej txheem no tseem txhawb kev ruaj khov los ntawm kev ua kom zoo dua cov khoom siv thiab txo cov pa roj carbon emissions. Los ntawm kev ua raws li cov lus qhia ntxaws ntxaws, koj tuaj yeem ua kom zoo thiab ua haujlwm ntawm cov pwm pwm, tiv thaiv kev tsim khoom tsis ua haujlwm thiab tswj kev ua haujlwm zoo.

| Tau txais txiaj ntsig | Kev piav qhia |

|---|---|

| Sustainability | Kev siv thev naus laus zis hauv kev txhaj tshuaj molding daws teeb meem ib puag ncig los ntawm cov khoom siv ruaj khov thiab cov txheej txheem ua tau zoo. |

| Txo cov pov tseg | Txhaj tshuaj molding txo cov khoom pov tseg, tsuas yog siv cov yas uas xav tau rau cov khoom kawg. |

| Zog Efficiency | Cov tshuab niaj hnub no yog tsim los rau kev txuag hluav taws xob, txo cov nqi ua haujlwm. |

FAQ

Dab tsi yog precision txhaj molding?

Precision txhaj tshuaj molding yog txheej txheem tsim khoom uas tsim kom yooj yimyas qhov chawnrog cov neeg raug siab thiab pov tseg tsawg heev.

Yuav ua li cas precision txhaj molding txhim kho roj efficiency?

Los ntawm kev tsim cov khoom sib sib zog nqus, kev txhaj tshuaj molding yuav txo tau lub tsheb hnyav, ua rau kev txhim kho roj thiab kev ua haujlwm zoo.

Cov ntaub ntawv dab tsi feem ntau siv hauv kev txhaj tshuaj molding rau cov khoom siv tsheb?

Cov khoom siv feem ntau suav nrog polyamide (PA), polyphenylene sulfide (PPS), thiab ntau yam thermoplastics uas muaj cov kav ntev thiab kub ua haujlwm.