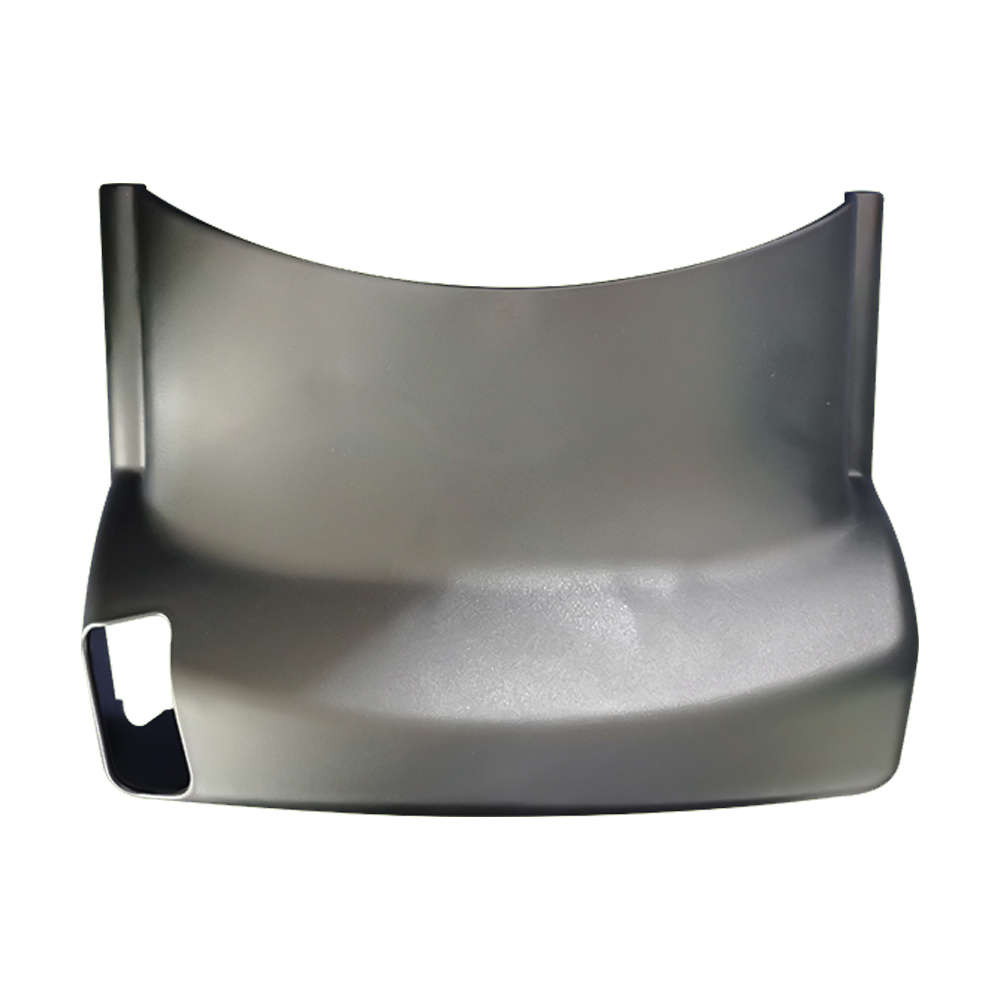

Split yas bushing

Split yas bushing - cov khoom siv ruaj khov thiab raug nqi zoo rau kev siv tshuab

Split yas bushings yog ib qho tseem ceeb hauv kev lag luam machinery. Lawv tau tsim los muab kev txhawb nqa tsim nyog rau kev sib hloov shafts thaum txo kev sib txhuam. Peb cais cov yas bushings muab kev ua tau zoo heev, superior durability thiab tsis tshua muaj nqi-zoo. Hauv tsab xov xwm no, peb yuav tham txog cov ncauj lus kom ntxaws, qhov zoo, kev siv, thiab kev teeb tsa ntawm peb cov yas sib cais.

Khoom Paub meej:

Peb cov yas sib cais bushings yog tsim los siv cov ntaub ntawv qib siab uas ua kom muaj kev ruaj ntseg zoo thiab ua haujlwm ntev. Cov bushings no muaj nyob rau hauv ntau qhov ntau thiab tsawg, duab, thiab cov ntaub ntawv, suav nrog nylon, POM, HDPE, thiab PTFE, kom phim cov kev cai tshwj xeeb ntawm peb cov neeg siv khoom. Tsis tas li ntawd, peb cov yas yas sib cais muaj ob lub halves, uas yooj yim rau kev teeb tsa ntawm bushing ntawm lub ncej yam tsis muaj kev cuam tshuam cov khoom.

Khoom nta:

Peb cov yas sib cais bushings muaj ntau yam tshwj xeeb uas ua rau lawv haum rau ntau hom kev lag luam. Ua ntej, kev sib cais tsim ntawm bushing kom yooj yim installation, hloov, thiab disassembly ntawm bushing tsis tas yuav tshem tawm lwm qhov chaw. Qhov thib ob, cov bushings yog tsim los txo cov suab nrov thiab kev co thiab txo qhov muaj peev xwm ntawm kev siv tshuab. Thib peb, lawv tuaj yeem tiv taus cov loads siab thiab ceev, uas ua kom ntseeg tau thiab ua haujlwm zoo ib yam.

Product Advantages:

Peb cais cov yas bushings muab ntau yam zoo, ua rau lawv xaiv zoo tshaj li cov khoom siv ntoo. Ua ntej, phua yas bushings yog tus nqi zoo vim lawv tsim, uas txo cov sij hawm sib dhos thiab disassembly, thiab cov nqi tu. Qhov thib ob, kev sib cais tsim ua rau lawv hloov pauv cov khoom siv uas tsis muaj qhov tsis zoo ntawm kev sib dhos tag nrho, ntxiv txo cov nqi hloov. Thirdly, cais bushings txo qhov kev pheej hmoo ntawm kev puas tsuaj rau lub ncej thiab lwm yam khoom thaum lub sij hawm installation, txiav txim siab txo downtime.

Khoom siv:

Peb cov yas yas sib cais yog tsim rau siv ntau yam kev lag luam, nrog rau cov tshuab conveyor, cov twj tso kua mis, thiab cov khoom siv ua zaub mov, rau npe rau ob peb tug. Lawv tuaj yeem siv rau hauv feem ntau kev lag luam uas xav tau kev sib hloov thaum txo kev sib txhuam thiab suab nrov. Tsis tas li ntawd, lawv yog qhov zoo tagnrho rau siv nyob rau hauv ib puag ncig hnyav uas ua rau cov tshuab ua paug, kev co, thiab cua sov.

Khoom Installation:

Kev txhim kho ntawm peb cov yas sib cais yog qhov yooj yim, thiab tuaj yeem ua tau los ntawm cov kws kho tsheb feem ntau muaj peev xwm. Txoj kev sib cais tso cai rau cov bushing kom swb mus rau qhov loj ntawm tus ncej yam tsis tas yuav muaj cov cuab yeej tshwj xeeb. Ob lub halves ntawm bushing tuaj yeem compressed kom tuav ruaj ntseg ntawm lub ncej. Ntxiv mus, peb cov bushings tuaj nrog cov lus qhia kev teeb tsa uas muab cov lus qhia ntxaws txog yuav hloov lossis nruab cov bushings kom raug.

Hauv kev xaus, peb cov yas sib cais bushings muab cov nqi tsim nyog, txhim khu kev qha, thiab yooj yim rau kev lag luam machinery. Nrog lawv cov yam ntxwv tshwj xeeb thiab qhov zoo, cov bushings no txo cov nqi kho, ua kom cov cuab yeej siv tau ntev, thiab txhim kho kev ua haujlwm tag nrho. Tiv tauj peb hnub no kom paub ntau ntxiv txog peb cov yas yas sib cais los yog muab qhov kev txiav txim.